Overview:

Electro-permanent magnetic clamps (EPMCs) are used to produce large reluctance force to rigidly clamp ferromagnetic materials without the need for a continuous power supply. In this project, such a clamp was designed and optimized to generate a clamping reluctance force high enough to hold a work piece during machining. The design process was three-pronged:

- A primary 1D Magnetic circuit analysis was carried out in Simulink to reverse-determine the necessary starting dimensions of the required force value.

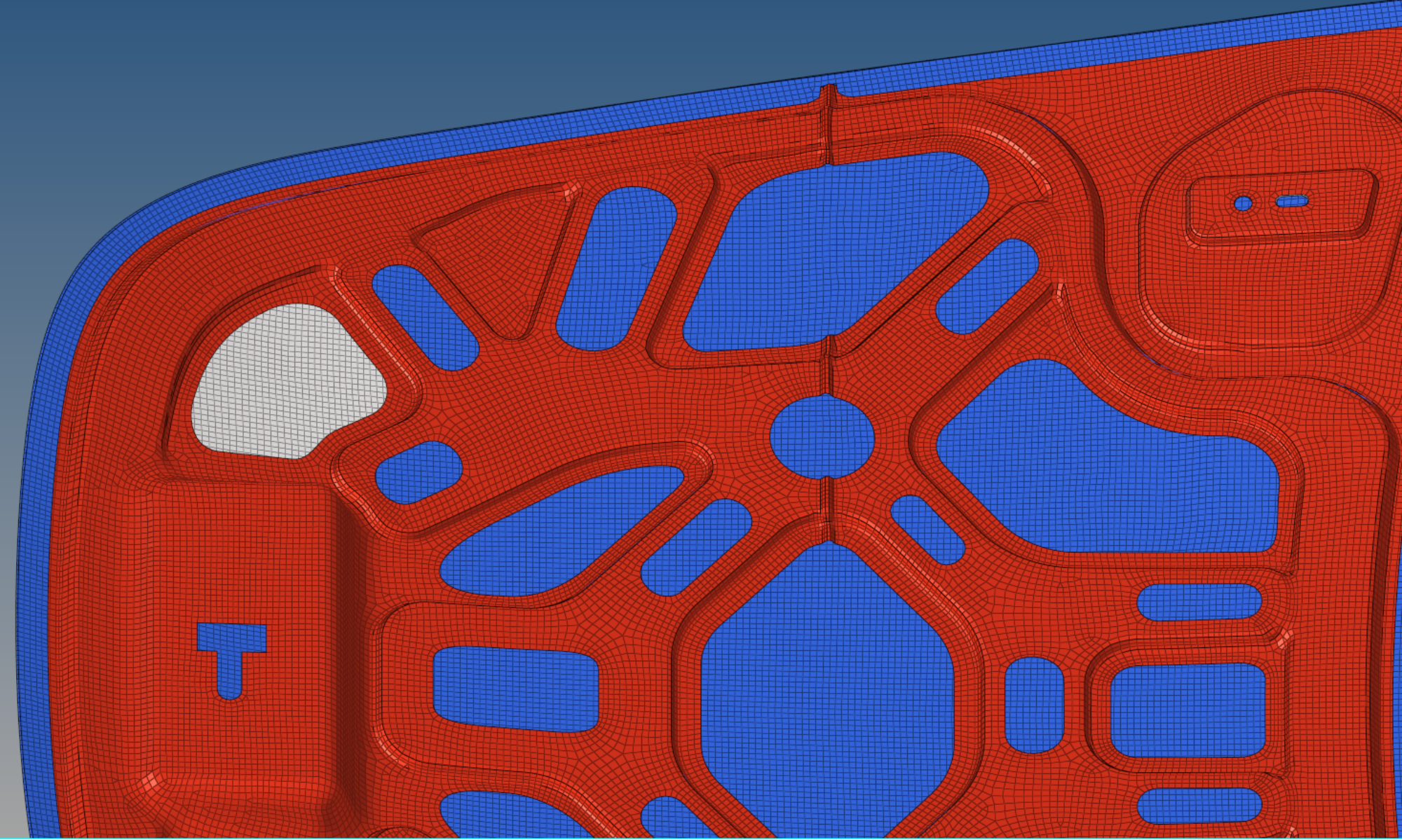

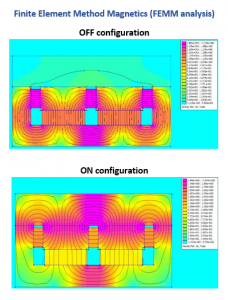

- An 2D model of the system was created and iteration process was automated by interfaced Matlab with LAU Script from FEMM package.

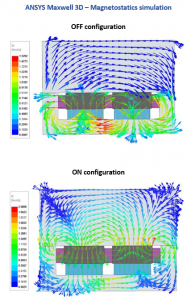

- The FEMM results were validated using ANSYS Maxwell 3D magnetostatic simulations.

Optimization constraints in design:

- The depth and length of each Pole-pieces (Grade 1020 steel) are 50 mm x 50 mm.

- The two Poles-pieces should be 60 mm apart from their centre.

- The cross sections of the AlNiCo magnets are constrained by the dimensions of the coil bobbins and shall be limited to 46 mm.

- There is air-gap between upper surface of the clamping device and the workpiece of atleast 0.1 mm. Air-gap is a biggest reluctance to the linkage of magnetic flux.

Performance objective:

- A minimum reluctance force (clamping force) of 1500 lbs (approximately 6672 N) has to be applied on the workpiece in the “ON” position (When clamping required) along with a negligible force in “OFF” position (clamping not required).

- Optimization of the dimensions of the steel poles and clamping case, the sizes and grades of the PMs (NdFeB and AlNiCo).

- Limit the flux linkage region to only Clamp body when in 'OFF' state.

- Restrict the saturation of magnetic flux generation to 1.8 Tesla only.

Results attained:

- A clamping force of 6673.7 N in 'ON' & 20.923 N in 'OFF' was met for the final optimum design.

- Suitable AlNiCo & NdFeB grades were found which satisfied the force requirements as well as dimensional objective requirements.

- The design was improved dimensionally by 5.93 % (in volume) when switched from 2D FEMM method to 3D ANSYS Maxwell method.

Finite Element Method Magnetics (FEMM analysis)