In the field of medical devices and surgery equipments, Finite Element analysis plays a major role in predicting the efficiency of the tools used towards curing impaired biological part and to test their reliability for the treatment option.

In cardiovascular clots, the damaged arteries and veins are nothing but mechanical systems able to constrict blood flow passage. The cardiovascular wall can be thought of as soft materials with certain amount of physical elasticity.

Coronary Stents have been the greatest inventions as a remedy. Stents are easy-deploy tubular scaffolds that have certain amount of plasticity and ability cage plaqued area without distorting its own shape in expanded form.

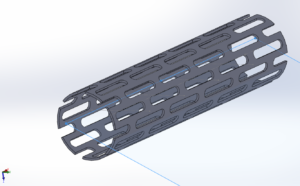

In this case study, i have modeled a basic stent geometry using SolidWorks and modeled balloon in Abaqus part modeling.

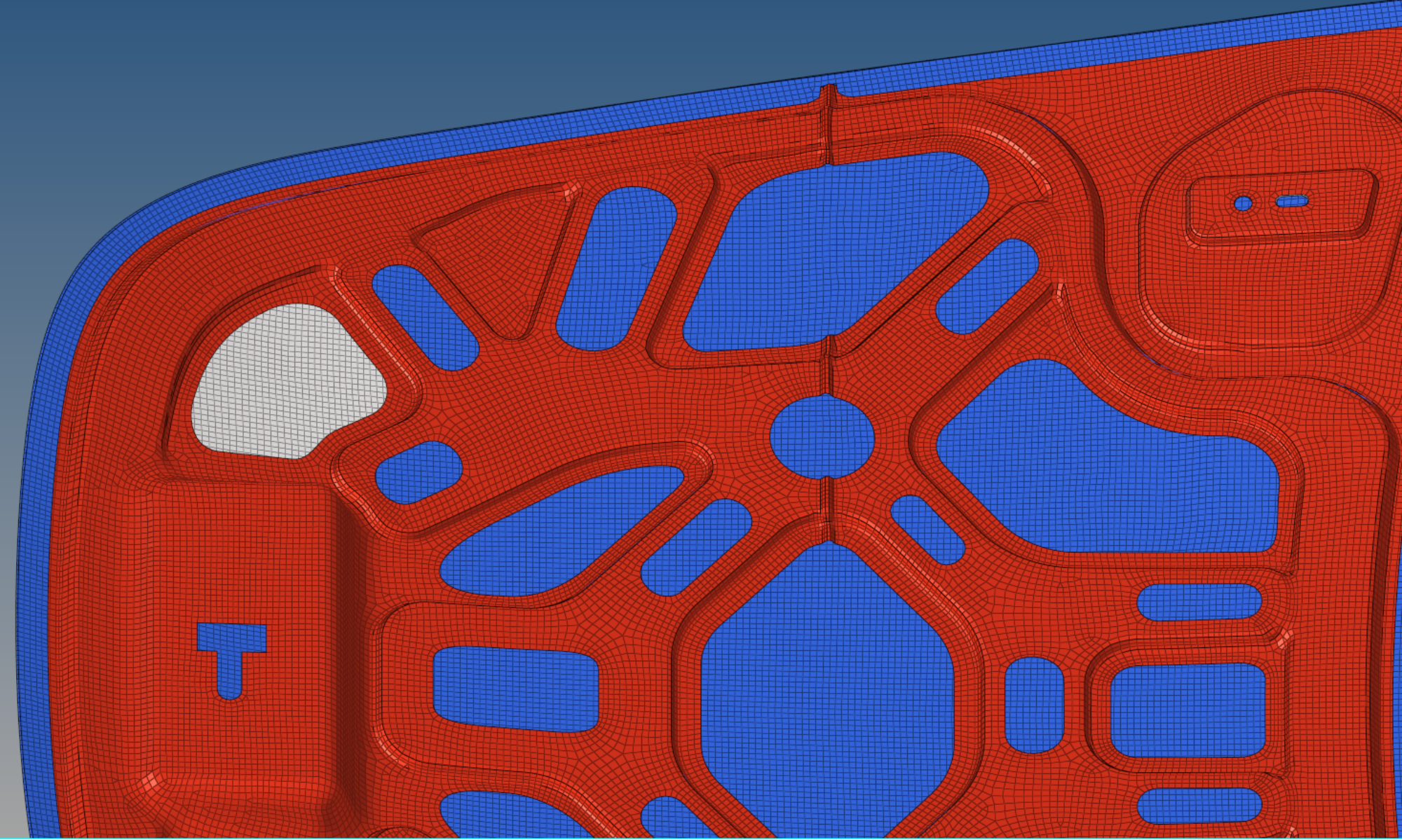

The elastic material properties were assumed for stent scaffold and balloon was modeled with hyperelastic material parameters. And a tangential surface-to-surface (Tie) contact was defined between stent and balloon.

Performing an implicit analysis for such a quasi-static process is befitting as the process developes over a few seconds not bringing in the inertia effects. In the animation below, we can see how the expansion of balloon causes strains in the material of stent, & how the distal ends of the stent body are getting uprooted signaling to a possibility of artery wall abrasion due to it.